Babylock Verve Problems: Troubleshooting!

Issues with the Baby Lock verve machine are common with its customers. Yet the majority of difficulties can be solved without the assistance of a professional.

So, how to fix Babylock verve problems?

The baby lock verve sewing machine has problems including Needle breaking, Feed dogs being stuck, Fabrics Puckering, buttonhole difficulties and many more. To solve this problem you need to clean the sewing machine, replace the needle, use an additional stabilizer, fold fabrics twice etc

Keep reading for an in-depth analysis of a particular issue and its resolution. Stay with us, because we’ve analysed the issue in depth.

5 Common Babylock Verve Problems and Solutions

Bellow table gives a brief about Babylock Verve Problems and Solutions

| Problem | Reason | Solution |

| Needles breaking | Not cleaning your sewing machine regularly | Clean the sewing machine and replace the broken needles. |

| Don’t Get the same fabric coverage | With Different cloth densities | Use an additional water-soluble stabilizer or topping. |

| Feed Dogs Are Stuck in the Down Position | Needle turns into low or feeds dogs lever issues. | Make sure your needle is turned as high and check the manual for lever issues. |

| The fabric is Puckering | The puckering problem may cause due to incorrect tension or fabrics problem or sewing machine problems | For solving you can loosen the tension, fold the thin fabrics twice or can use a small size needle. |

| Difficulties while making Buttonholes in polar Fabrics | Wider than the normal fabrics | Use an additional stabiliser or check the machine too if there is an option for Polar fleece fabrics. |

Problem 1: Needles breaking

While working with your baby lock verve sewing machine sometimes the needles of your sewing machine may break. Or sometimes it may be hit with bobbins due to dirt and it will be broken.

Reason:

You need to clean your Sewing machine on a regular basis. If you do not clean it regularly there might be some problems. And Most frequent problem due to not cleaning the sewing machine is needles breakings.

Solution:

For solving this problem you need to clean your sewing machine on a regular basis.

To clean a sewing machine you always need a sewing machine owner manual. Below given the steps to clean your sewing machine.

Needed Tools:

- Baby lock verve Sewing machine owner manual

- Barely damp paper towels

- Screwdriver

- Lint brush or soft bristled paint brush

- Tweezers

- Sewing machine oil

- Soft cloth

- New baby lock verve sewing machine needle

Step 1: First, clean all the surfaces of the sewing machine with the damp cloth until you feel that there is no dirt remaining.

Step 2: Take the lint brush to clean all the crevices on the top of the sewing machine.

Step 3: Remove the Bobbin cover and keep all the parts in a safe place.

Step 4: Remove the Bobbin.

Step 5: Remove the Arm and clean it with damp clothes.

Step 6: Remove the presser foot using the screwdriver.

Step 7: Loosen the screw and remove the broken needle

Step 8: Remove the needle plate of the sewing machine, take the Lint brush and clean every little nook and cranny. Also, clean the bobbin holder carefully.

Step 9: After that apply a small amount of sewing machine oil. And remove dirt with the Tweezers.

Step 10: Finally, put everything back together with a brand new needle.

For more knowledge, you can see the video.

By proper cleaning, you can solve sewing machine fabric eating problems.

Problem 2: Don’t Get the same fabric coverage

You may not find the same fabric coverage, when you are working with different types of fabrics such as terry cloth or velvet cloth.

Reason:

It causes mainly due to cloth density. Cloth density varies based on the different types and materials of the clothes. So it may cause fabric coverage problems.

Solution:

For solving this problem you can follow the below instructions:

- In addition to your sewing machine’s standard stabiliser, you should put a water-soluble stabiliser or add topping on top of your fabric. This will provide a flat, even surface upon which to sew.

- When using a water-soluble stabiliser and seeing no results. Then, based on the size of the design space you are filling, you should raise your fabric density somewhat. Keep in mind that a greater region may accommodate a higher population density.

Problem 3: Feed Dogs Are Stuck in the Down Position

While working on the sewing machine, sometimes your feed dogs are stuck in down positions. Sometimes it remains stuck after you take off the platform also. For this problem, embroidery can be loose also.

Reason

For grabbing the fabric and feeding it through the machine, feed dogs are often set to the “up” position. Put it “down” when it’s appropriate to do so. When the feed dog’s lever is broken or the needle is turned in too far, the mechanism becomes stuck.

Solution:

For solving this problem you need to follow the below steps

- Making sure the needle is set as high as it can go.

- Turning the needle in a clockwise direction will cause the feed dogs to rise over the needle plate.

- Verify the feed dog lever. The feed dog lever should be moved up if it is pointing down.

- To find out how the lever should appear while the feed dogs are up, see the user handbook.

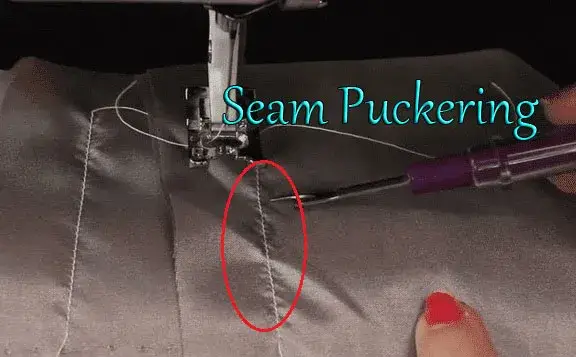

Problem 4: The fabric is Puckering

Puckering is a common sewing flaw that manifests as a gathered or bunched-up appearance along the stitching line. An unpleasant rippling look may be seen along the seam.

Reason:

The fabric puckering may cause many reasons, some of which are

- Puckering due to incorrect tension

- Puckering due to problems with fabrics

- Puckering due to sewing machine problems

- Puckering due to the use of the wrong needle

- And, puckering on thin fabrics

Solution:

For solving this problem you can follow the below instructions.

- Try loosening the tension.

- Double-fold the flimsy materials for reinforcement.

- Try using a smaller needle. The recommended size is 9

- For an almost undetectable hem, try using cotton embroidery thread, which is thinner.

Problem 5: Difficulties while making Buttonholes in polar fleece Fabrics

During working on the sewing machine, sometimes it is difficult to make buttonholes on the polar Fleece fabric.

Reason:

Fleece is a synthetic polyester fabric that is both lightweight (compared to wool) and very adaptable. Polyester is made from terephthalic acid and ethylene glycol, both of which are petroleum byproducts.

And this type of fabric is wider than normal fabrics. So it’s hard to create buttonholes on polar fleece fabrics.

Solution:

For solving the problem follow the below instructions.

- To create the buttonhole, place a tear-away stabiliser below the desired location.

- This keeps the feed dogs from being sucked into the cloth and disrupting the feeding process.

- Spread some water-soluble stabiliser over the area of the cloth that will become the buttonhole.

- If your sewing machine has an option, use the buttonhole stretch setting.

How to Maintenance Your Baby Lock Verve?

To avoid the above problems you need maintenance your sewing machine regularly. In Bellow given the steps so that you can easily maintain your sewing machine.

The maintenance process is similar for sewing machines like CS7000x and CP100x also.

The maintenance process has two parts:

- Cleaning the machine

- Oiling on the machine

Cleaning the machine:

For cleaning the machine follow the above steps without changing the needle.

Oiling the machine:

Before oiling the machine keep in mind,

- Older machines feature red circles around their body openings. These are the areas that need to be oiled. Simply sprinkle a few drops into the holes and wipe away any lingering residue.

- In order to oil the internal components of certain machines, You may find instructions in the owner’s book on how to remove the top plate.

Follow these procedures to properly oil your machine:

- Switch off the power supply.

- Apply 1-2 drops of oil to the machine’s series of holes.

- For even oil distribution, run the machine for a few minutes with no thread or fabric in it.

- Remove any lingering oil from the machine’s exterior by wiping it down.

- To guarantee that the excess oil is absorbed and will not ruin the cotton fabric, sew a piece of cotton when threading the machine.

There are some more factors used for the maintenance of a sewing machine.

Frequently Asked Questions (FAQs):

Can you quilt with Babylock verve?

Yes, you can. When it comes to quilts, Verve is the ideal choice. Despite its small size, it has all the essential functions you may want, including 95 built-in embroidery patterns and 191 stitches. Furthermore, it is designed for speed, clocking in at a rapid 850 SPM.

Are Baby Lock machines high or low shank?

In point of fact, the Baby Lock Destiny that you have is a “mid-shank” machine. Make sure to utilise the adapter that came with your Destiny if you wish to use low-shank or high-shank feet with it.

Why is it called a Baby Lock sewing machine?

The first Baby Lock overlock sewing machine was produced in 1964. It was small enough to be used in the house, thus the name. This marked the introduction of the first home overlock machine under the Baby Lock brand.

Conclusions

Babylock verve problems can ruin your sewing machine using experience. And most of these problems occur for the lack of proper maintenance of your sewing machine. Try out these solutions for solving your problem.

Thank you, Happy sewing.